-

Email:sales@abfindia.co.in

-

Call Us: +91 - 9879 091 953

Email:sales@abfindia.co.in

Call Us: +91 - 9879 091 953

Used for molten material flaking

ROTARY DRUM FLAKER

Deep Feed Drum Flaker

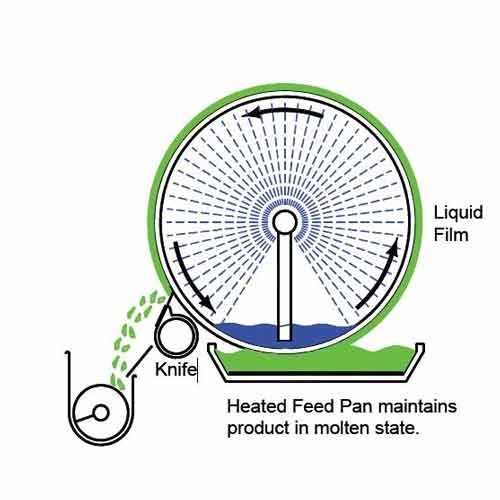

Cooling Drum Flakers are the most compact and efficient method to cool an incoming molten product to a solid flaked product utilizing thin film continuous cooling via conductive heat transfer. .

Cooling Drum Flakers are utilized in food, chemical, environmental, and pharmaceutical applications for products such as acetic acid, calcium chloride, caustic soda, edible oils, fatty acids, polyethylene glycol, steric acid, waxes and zinc stearate.

It consists of a rotating drum with a cooling liquid sprayed on the inside and a product specific application method for applying the molten product to the drum surface. Standard applications methods are; a dip feed pan usually used for low viscosity products, applicator roll usually used for heat sensitive products or agitator roll usually used for super-cooling products. The solidified product is 100% removed from the drum surface by ridged knife-bar assembly.

These types of machines are available in M.S. And S.S. construction. The kneader can be tilted by means of a mechanical system or manually and for bigger models beyond 250 Kgs we provided hydraulic tilting.

Hydraulic tilting system is provided with complete power pack, electric motor, pressure valves, pipes, fittings, cylinders and hoses which makes the tilting mechanism quick, easy and simple to operate.

1. Performance reached the level of foreign equipment

2. With a side scraper to avoid drum side accumulation of material

3. Compact equipment structure, small footprint

4. Half tube jacket tray, safe and reliable

5. Atomization cooling, cooling effect is good

6. CVT, adjustable drum speed

7. High drum precision

8. Adapt to a wide range, easy to operate and flexible

9. Multi-group scraper, flexible adjustment

10. Multi-functional, both knot and dry

Consisting of a rotating drum with a cooling liquid sprayed on the inside and a product specific application method for applying the molten product to the drum surface, standard applications methods are a dip feed pan usually used for low viscosity products, applicator roll usually used for heat sensitive products or agitator roll usually used for super-cooling products. The solidified product is 100% removed from the drum surface by ridged knife bar assembly.

Technical Specification :

|

Item No |

Specification mm |

Drum Surface Area | Motor Power HP | Barrel speed r/min | Size (mm) | ||

L | W | H | |||||

ABF-DF1 | Φ600×600 L | 1.1 | 2-3 | 0.3-15 | 1500 | 700 | 1500 |

ABF-DF2 | Φ750×1200 L | 2.8 | 3 | 0.3-15 | 3000 | 800 | 1800 |

ABF-DF3 | Φ1000×1000L | 3.1 | 3 | 0.3-15 | 2800 | 1200 | 2000 |

ABF-DF4 | Φ1000×1500L | 4.7 | 5 | 0.3-15 | 3400 | 1600 | 2400 |

ABF-DF5 | Φ1500×1500L | 7.0 | 5 | 0.3-15 | 3500 | 1500 | 2400 |

ABF-DF6 | Φ2000×1500L | 9.4 | 7.5 | 0.3-15 | 3500 | 2000 | 2700 |

Sigma Mixer with Extruder Screw

Deep Feed Drum Flaker